A12 LLDPE

Linear low-density polyethylene LLDPE is a substantially linear polymer commonly made by copolymerization of ethylene with longer-chain olefins.

Application

LLDPE used in the manufacturing of stretch wrap in transporting and handling boxes of durable goods, and as the common household food covering

A13 HDPE

High-density polyethylene (HDPE) High-density polyethylene or polyethylene high-density is a polyethylene thermoplastic made from petroleum. Semi rigid, Sinks in water, Resistance to moisture, permeability to gas

Application

HDPE Used as milk jugs, liquid laundry detergent bottles, outdoor furniture, margarine tubs, portable gasoline cans, drinking water distribution systems, water drainage pipes, and grocery bags.

A14 EVA

Ethylene-vinyl acetate (EVA), also known as poly (ethylene-vinyl acetate) (EVA), is the copolymer of ethylene and vinyl acetate. The weight percent of vinyl acetate usually varies from 10 to 40%, with the remainder being ethylene.

Application

EVA is one of the materials popularly known as expanded rubber or foam rubber.EVA foam is used as padding in equipment for various sports such as ski boots, bicycle saddles, hockey pads, boxing and mixed-martial-arts gloves and helmets, wakeboard boots, waterski boots, fishing rods and fishing-reel handles.Used as a shock absorber in sports shoes, for example.

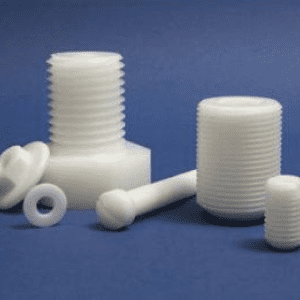

A31 PPH

Polypropylene Homopolymer (PPH) is the most widely utilized. PPH offers a high strength to weight ratio, this combined with good chemical resistance and weldability allows this material to be used in many corrosion resistant structures

Application

A31_PPH AdditionalInfo A31_PPH A31_PPH A31_PPH A31_PPH AdditionalInfo AdditionalInfo AdditionalInfo AdditionalInfo AdditionalInfo AdditionalInfo AdditionalInfo

A32 PPC

(PPC) is a colorless, non flammable, non reactive solid with no odor. See Product Description. Polypropylene Copolymer (PPC) is usually stored and/or transported as 25 Kg Bags or 1 MT FIBC jumbo Bags. It is used in raw material for plastic Processing industry..

Application

Data uploading soon...

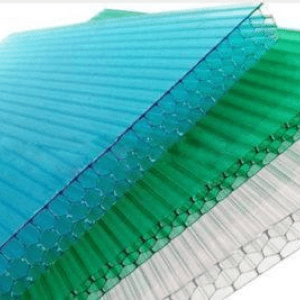

A33 PPR

PPR pipe is a straight and rigid cylindrical pipe, made from Polypropylene Random Copolymer plastic, produced through a continuous extrusion process. They are commonly offered in green or white color, and in outer diameter sizes ranging from 20mm to 110mm making the pipe walls far thicker than PVC/

Application

Data uploading soon...

A41 GPPS

General Purpose Polystyrene, often referred to in its acronym form GPPS, is made from a styrene monomer polymer through a process of suspension. The polystyrene is used in applications such as IT equipment, clear jewel boxes and other types of enclosures

Application

General-purpose polystyrene (GPPS) is used in the manufacture of disposable cutlery, plastic models of cars and boats, and smoke detector housings.

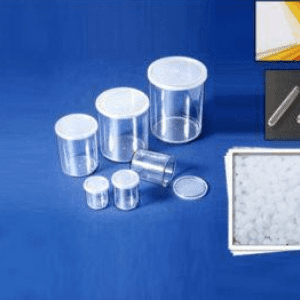

A21 Resin

PET, which stands for polyethylene terephthalate, is a clear, strong and lightweight plastic belonging to the polyester family. It is typically called "polyester" when used for fibers or fabrics, and "PET" or "PET Resin" when used for bottles, jars, containers and packaging applications.

Application

The biggest application is in fibers (in excess of 60%), with bottle production accounting for about 30% of global demand. It is also used in flexible packaging, photovoltaic modules, and waterproofing barrier in undersea cables

A22 Preform

A preform is an intermediate product that is subsequently blown into a polyethylene terephthalate (PET) container. Preforms vary in neck finish, weight, colour and shape, and are specifically designed to meet the needs of customers in different market segments.

Application

PET preforms are made from PET resin and are used in blow-molding processes for bottle production

A61 ABSS

Acrylonitrile butadiene styrene (ABS) is a terpolymer synthesized from styrene and acrylonitrile in the presence of polybutadiene. ABS is a light-weight material that exhibits high impact resistance and mechanical toughness. It poses few risks to human health under normal handling

Application

Used in many consumer products, such as toys, appliances, and telephones. For the majority of applications, ABS can be used between −20 and 80 °C, as its mechanical properties vary with temperature

A62 ABS/PC

Acrylonitrile butadiene styrene/Polycarbonate (ABS/PC) is a blend of PC and ABS. It provides unique combination of the high processability of ABS with the excellent mechanical properties, impact and heat resistance of PC.They fit into applications that require a high heat distortion temperature (95-125°C) and good toughness. They have excellent low temperature toughness, making them ideally suited for products that will see a broad range of temperature.

Application

Automotive: Instrument panel, pillars, seatbacks, structural components,Electronics: Portable hand-held devices, LCD panels, keypads, mobile phone bodies.

A64 PA6/66

Polyamide 66 (known as PA 66) is a type of polyamide or nylon. Nylon 66 is made of two monomers each containing 6 carbon atoms.Polyamide 6 (Or PA 6) is a polymer developed to reproduce the properties of PA 66 without violating the patent on its production.

Application

PA 6 and PA 66 are the two most common for textile and plastic industries. They have served as a substitute mainly for hemp, cotton and silk, in products such as parachutes, cords, sails, flak vests and clothing. Nylon fibers are useful in making fabrics, rope, carpets and musical strings, whereas, in bulk form, nylon is used for mechanical parts including machine screws, gears and power tool casings.

A65 PBT

Polybutylene terephthalate (PBT) is semi-crystalline polyester. PBT is resistant to solvents, shrinks very little during forming, is mechanically strong, heat-resistant up to 150 °C (or 200°C with glass-fiber reinforcement) and can be treated with flame retardants to make it noncombustible.

Application

Insulator in the electrical and electronics industries.Automotive construction as plug connectors and in households products.Keycaps of high end laptops because the texture is highly resistant to wear and discoloration due to UV radiation Yarn for incorporation into sports wear.

A67 PMMA

Poly methyl methacrylate (PMMA) is a transparent thermoplastic. It is an economical alternative to polycarbonate (PC) when tensile strength, flexural strength, transparency, polishability, and UV tolerance are more important than impact strength, chemical resistance, and heat resistance.PMMA does not contain the potentially harmful bisphenol-A subunits found in polycarbonate and is a far better choice for laser cutting. It is often preferred because of its moderate properties, easy handling and processing, and low cost.

Application

Substitute for glass for items such as aquariums, buttons, motorcycle helmet visors, aircraft windows, viewing ports of submersibles, and lenses of exterior lights of automotive. Also used to make signs, including lettering and logos.In medicine, it is used in bone cement and to replace eye lenses.

A68 POM

Polyoxymethylene (POM) is characterized by its high strength, hardness and rigidity down to −40 °C.POM is opaque white because of its high crystalline composition but can be produced in a variety of colors.

Application

Applications in injection molding include high-performance engineering components such as gear wheels, ball bearings, and lock systems.Widely used in the automotive and consumer electronics industry. Also used in precision parts requiring high stiffness, low friction, and excellent dimensional stability.

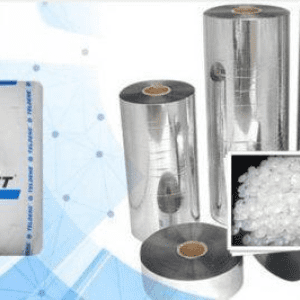

A69 POP/POE

Polyolefin plastomers (POP) and polyolefin elastomers (POE) bridge the performance gap between conventional plastics such as polyethylene (PE) and conventional elastomers like ethylene propylene diene monomer (EPDM).POP/POE assist in fulfilling sophisticated sealing, flexibility, compatibility and processability requirements: They combine many of the physical properties of a rubber with the processing advantages of a thermoplastic material.

Application

Stretch hood packaging, cling film, intermediate layer between PE and metallized PP layers, automatic packaging film, impact modifier in PE and PP, filler level increase in masterbatch manufacturing, injection molding with enhanced thermo-mechanical properties.

A70 TPE

Thermoplastic elastomers (TPE) are copolymers, usually blend of plastics and rubbers, that consist of materials with both thermoplastic and elastomeric properties.TPEs have outstanding thermal properties and material stability when exposed to a broad range of temperatures. TPE materials have the potential to be recyclable since they can be molded, extruded and reused like plastics

Application

TPEs are heavily used in extrusion and injection molding Large applications in the automotive sector and in household appliances sector. About 40% of all TPE products are used in the manufacturing of vehicles. TPEs are also widely used for catheters in the medical industry offering a range of softness ideal for patients.

A71 TPO

Thermoplastic polyolefins (TPO) refer to polymer/filler blends usually consisting of some fraction of a thermoplastic, an elastomer or rubber, and usually fillers. Thermoplastics may include PP, PE and block copolymer-PP. Common fillers include talc, fiberglass, carbon fiber

Application

Outdoor applications such as roofing frequently contain TPO because it does not degrade under solar UV radiation, a common problem with nylons.TPO is used extensively in the food packaging and automotive industry. TPO is easily processed by injection molding, profile extrusion, and thermoforming

Dow Polyolefin Elastomer 3 Mfi Engage 8450

Engage® 8450 polyolefin elastomer is an ethyleneoctene copolymer that performs well in a wide range of thermoplastic elastomer applications. It has excellent compatibility with other polyolefins, allowing for efficient blending and coextrusion. Engage® 8450 provides excellent flow properties and is efficiently cross-linked by peroxide, silane, or irradiation. When cross-linked, it gives exceptional heat aging, compression set, and weather resistance properties.

Application

LG Polyolefin Elastomer Lucene LC670

LUCENETM LC670 is an ethylene-1-octene copolymer produced using LG Chem’s metallocene polymerization catalyst and solution process technology.

LUCENETM LC670 is an excellent impact modifier for plastics and offers unique performance capabilities for compounded products.

Sabic Polyolefin Elastomer Fortify C5070d

sabic fortify c5070d is an ethylene octene copolymer produced by solution polymerization using metallocene catalyst. This product is available asfree flowing pellets. Sabic fortify c5070d is designed as a low density and high performance copolymer modifier to provide superior impact properties and flowcharacteristics.