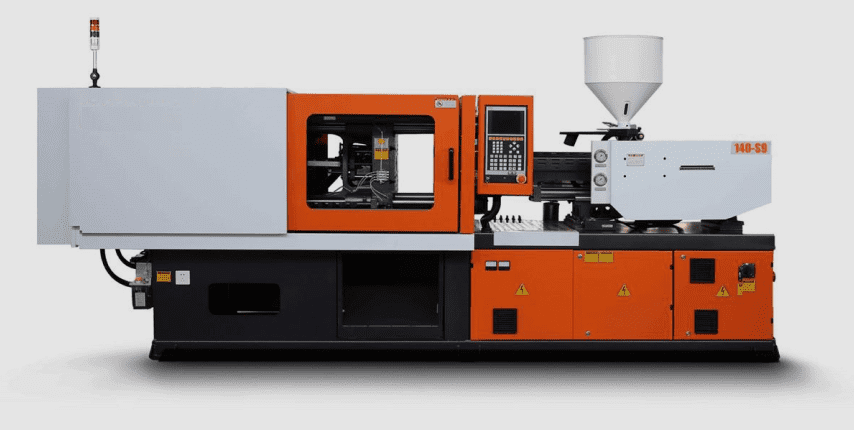

INJECTION MOULDING MACHINES

Super-Precision Injection molding machine with full-color LCD control and servo-valve fully closed loop hydraulics. S2/S3 Series has V-Line technology that no other have. Features of this V-Line te

Specification

- Capacity : from 30 Tons to 2500 Tons clamping force

- PLC or Microprocessor control systems, high output and fast cycle production

- Energy-saving hydraulic reduces operating cost to minimum

- Operation is highly user-friendly

- "ISO 9001" and "CE" certified machines

- Specially developed machines for PET Performs and PVC Fitting Applications

- Extended Service Warranty offered.

AUXILLARY EQUIPMENTS

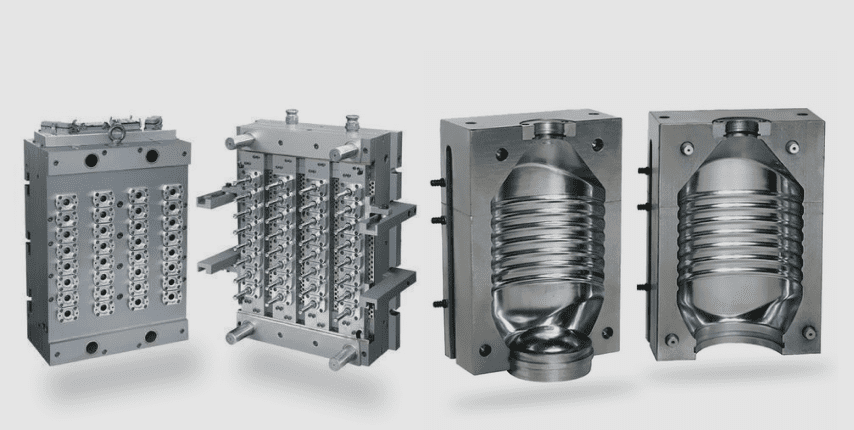

INJECTION/BLOW/PET MOULDS

Blow molding is a manufacturing process in which air pressure inflates heated plastic in a mold cavity. It is used for the production of hollow plastic parts with thin walls, such as beverage bottles cosmetic containers and pharmaceutical packaging.

Specification

- Made of best quality steel with proper cooling systems

- Diamond-polished hard chrome plated and sand blasted

- Fully automatic, fast production, multi-cavity moulds

- Completely made on CNC Machines

- Moulds for Household, Industrial, Furniture and Thin Walled Applications.

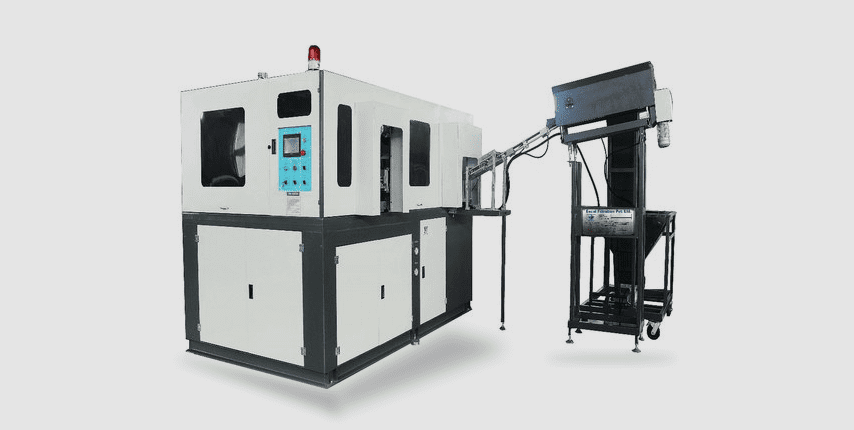

PET STRETCH BLOW MOULDING MACHINE

These machines are designed for operating in the automatic cycle. These machines are used for manufacturing bottles and jars of size 25ml to 25 ltr. capacity made from polyethylene Terephatalate (PET) preform by thermal processing and stretch blowing.

Specification

- Hydro pneumatically operated semi and fully auto machine

- Blowing capacity from 50 ml to 20 Liters Jars

- Microprocessor controlled gives optimum bottle quality

- Single and multi-cavity gives high production output

- Simple operation and lesser maintenance

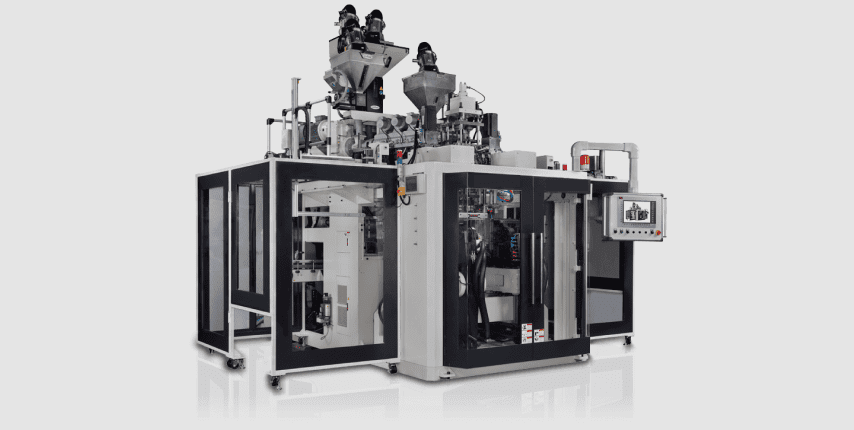

BLOW MOULDING MACHINES

These machines are designed for operating in the automatic cycle. These machines are used for manufacturing bottles and jars of size 25ml to 25 ltr. capacity made from polyethylene Terephatalate (PET) preform by thermal processing and stretch blowing.

Specification

- Fully automatic machines. Capacity : from 50 ml to 200 liters

- PLC or Microprocessor control systems, multi point parison control system from Moog or Yuken

- Single or double station, with or without de-flashing systems

- Single or multi head with view strip Simple in operation, more versatility and high output Machines.

- Extended Service Warranty offered.

Chiller Plant

- Compact is size, in built SS Tank, with power saving system

- European made compressor for effective cooling

- Air Cooled / Water Cooled models available.

Cooling Tower

- Light Weight Designsss

- Made of FRP material for corrosion resistance and longer life

- Honeycomb designed PVC fill for better cooling

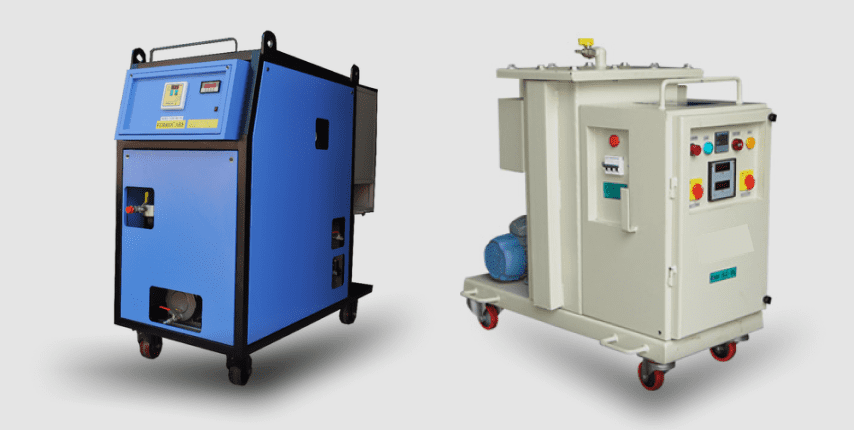

OIL CLEANING SYSTEM & LVDH

These machines are designed for operating in the automatic cycle. These machines are used for manufacturing bottles and jars of size 25ml to 25 ltr. capacity made from polyethylene Terephatalate (PET) preform by thermal processing and stretch blowing.

Specification

- Using this equipment can use same hydraulic oil for many years

- Solutions for all hydraulic problems in machine

- Works on electrostatic principles can remove insoluble particles of independent of size

Oil Cleaning System

- Ultimate Water removal through oil re circulation to achieve free water content, soluble gases and air

- It works on Low vacuum dehydration and de-gasification